05 Scheduled Maintenance

Scheduled Maintenance

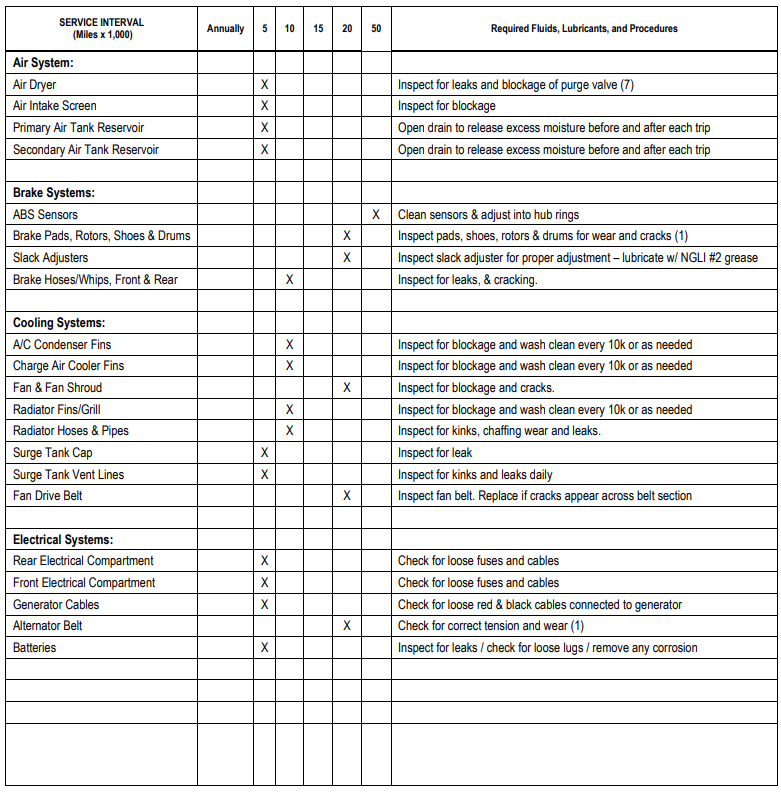

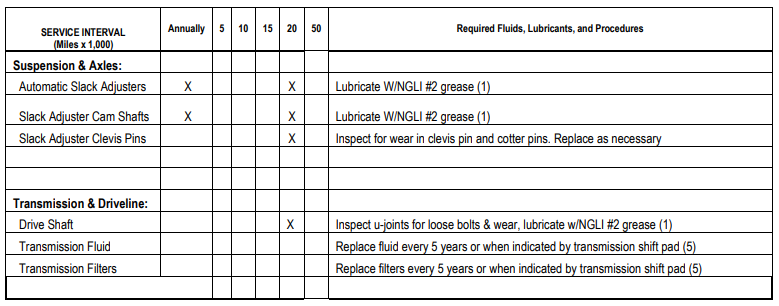

(1) Replace / inspect at stated mileage interval or every 12 months, whichever occurs first.

(2) Re-torque all wheel nuts after the first 100 miles, then every 10K miles thereafter.

(3) Factory filled with synthetic oil. Do not mix with mineral oils. Change fluid every 3 years or 50K miles.

(4) For best tire life and handling, alignment of front axle is recommended every 15K miles.

(5) Factory filled with Allison approved TES-295 fluid. To maintain these service intervals, fluid must not be mixed with Dexron or other fluids.

(6) Replace filter when indicator shows 25 inches or every 12 months, whichever occurs first.

(7) Replace desiccant cartridge every 36 months.

(8) Change fluid every 5 years or 50K miles.

(9) Factory filled with 80W90 mineral oil. Do not mix with synthetic. Change fluid every 3 years or 50K miles.

(10) Drain, flush, and refill with new antifreeze/coolant every 5 years. Only use coolants that meet or exceed Cummins requirements. Refer to appropriate Cummins literature for specifications. 2009 - 2016 model year coaches were factory filled with Shell Rotella ELC. 2017 -current models are factory filled with Old World Final Charge Global.

(11) Vehicles with RL80 front suspensions require no hub maintenance for 600,000 miles. Vehicles with RL67, and RL77 front axles require no hub maintenance for 300,000 miles.

Fluids

Engine Oil

The primary oil recommendation for the ISL / ISX engine is a high-quality SAE 15W-40 oil with API classification CJ-4 that meets CES-20081 standards. If the engine is to be consistently operated in extreme cold temperatures, -15°C (5°F), an SAE 5W-40 full synthetic oil is recommended. The Cummins engine in your coach was factory filled with Shell Rotella 15W-40 motor oil.

Cummins does not recommend special break-in oils for this engine. The factory fill oil can be run until the first oil change interval is reached.

Cummins does not recommend the use of aftermarket oil additives in their engines. High-quality 15W-40 engine oils with API classification CJ-4 meeting CES-20081 standards are precisely blended with the necessary additives. Additional additives are not necessary to enhance the oil performance.

Please refer to your Cummins ISL / ISX Owner’s Manual for more details on engine oils, and other engine maintenance.

Engine Coolant

The engine cooling system in your coach was factory filled with Old World Final Charge Global, Nitrite-Free Coolant. Old World Final Charge Global is a fully formulated, organic acid technology (OAT) coolant designed to protect all metals within the cooling system.

Do not mix or dilute the coolant in your coach with water, or other non-compatible coolants. If you need to top off your cooling system use only Old World Final Charge Global 50/50 premixed coolant. If the coolant does become diluted with water, or another non-compatible coolant a complete drain, flush, and refill of the cooling system is required.

Test the coolant in your coach for freeze protections, and inhibitors every 5000 miles, or at least twice annually. Test strips can be purchased from Old World Industries or one of its distributors.

The engine coolant in your coach should be replaced every 5 years. Drain, flush, and refill with new coolant. Be sure to use a coolant that meets are exceeds Cummins Engineering Standard, CES-14603. Please refer to your Cummins ISL / ISX Owner’s Manual for more details on the required coolant specifications.

IMPORTANT! When refilling the cooling system follow these instructions:

1) Remove surge tank lid/ radiator cap. (located on the surge tank)

2) Fill radiator through the surge tank (5 GPM max)

3) Once coolant is visible and halfway up the sight glass on the surge tank, start and run engine at idle for one minute, then at high idle for an additional two minutes.

4) Return engine to idle and if necessary, top off surge tank until coolant is visible halfway up the sight glass and close lid tightly.

NOTE: A complete drain, flush, and refill should be done at an authorized service center.

Diesel Exhaust Fluid (DEF)

DEF (diesel exhaust fluid) is used to reduce the NOx (nitrogen oxides) emissions from your engine exhaust system. DEF is non-flammable, non-toxic, and non-polluting. DEF can be corrosive to certain materials. If DEF is spilled, rinse and clean the area immediately with clear water.

It is recommended that you only use DEF certified by the American Petroleum Institute (API) in your vehicle. Look for this symbol on the container, or dispensing system to identify the fluid has been certified by the API.

DEF has a limited shelf life. Normal shelf life is around 18 months if stored in a sealed container at temperatures between 23°F and 77°F. DEF should not be stored in direct sunlight as this will reduce the shelf life of the product. If your coach is in storage for a period of 6 months or longer you should have the condition of the DEF tested before use. Testing should be done using a DEF refractometer. The DEF should show 32.5% Urea concentration, +/- 1.5%. If the DEF test outside of this parameter the tank should be drained, flushed with distilled water, and filled with new DEF.

DEF consumption will vary depending on your driving habits, and operating conditions. Generally DEF consumption will be 2 to 4 gallons for every 100 gallons of diesel fuel burned for the ISL engine. Consumption on the ISX engine will be higher. ISX engines will consume 3 to 6 gallons of DEF for every 100 gallons of fuel burned.

DEF freezes around 12°F. The DEF system on your vehicle is designed to accommodate this condition and does not require any intervention from the operator.

NEVER add anything other than new or known good DEF to the tank. If the tank is accidently contaminated by another fluid the tank should be drained, flushed with distilled water, and filled with new DEF.

Differential Oil

The differential in your coach was factory filled with Shell Spirax 75W-90 full synthetic lubricant. The fluid level should be checked every 10K miles. If make-up oil is required use only full synthetic 75W-90 lubricants. Never mix mineral oils with synthetic lubricants.

The differential oil should be changed every 3 years or 50,000 miles, whichever occurs first.

Transmission Fluid

The transmission in your coach was factory filled with Shell Spirax S6 A295 synthetic fluid. Spirax S6 A295 is an Allison approved TES-295 fluid. Allison approved TES-295 fluids extend both the service intervals, and the warranty for your transmission. Continued use of TES-295 fluid provides extended warranty coverage up to 5 years or 200,000 miles whichever occurs first.

Transmission fluid should be checked on a regular basis. It is recommended to check fluid at the end of the day when the transmission is at full operating temperature. Fluid should be checked with the park brake set, the engine running at idle, the transmission in neutral, and the transmission temperature above 140°F.

Transmissions do not consume fluid. If you find the need to regularly add fluid to your transmission a leak has developed and you should seek service from an Allison authorized dealer as soon as possible.

Change the transmission fluid and filter when indicated by the illumination of the transmission “wrench icon” on the shift selector, or every 5 years, whichever occurs first.

Please refer to your Allison Transmission Operators Manual for additional information on transmission fluids, and other transmission maintenance.

Lubrication Points

Maintenance Parts

Primary Fuel Filter/Water Sep W/WIF sensor

Cummins Filtration part # FS1003 Tiffin part # 31647

Secondary Fuel Filter

Cummins Filtration part # FF63009 Tiffin part # 5059830

Engine Oil Filter

Cummins Filtration part # LF9009 Tiffin part # 5024652

Engine Air Filter

Parker/Racor # 062891010 Tiffin part # 5028577

Serpentine Belt

Cummins part # 4937693 Tiffin part # 5042760

AC Belt

Gates part #K080435 Tiffin part # 5027678

For assistance with your Tiffin PowerGlide Chassis

Please contact one of the following chassis specialists at Tiffin Motorhomes, Inc.

256-356-8661

Service

Greg Dees

Billy Payne, extension 3862

Ricky Brown, extension 3861

Parts

Heath Thorne, extension 3860

Mechanical Engineering

Corbette Davis, extension 2125

Electrical Engineering

Chris Struzik, extension 2363

Plant Manager

Gary Harris, extension 2288

Please have your Chassis VIN # ready when you call.