04 Cummins ISL Engine

EPA Mandates

The Environmental Protection Agency (EPA) mandates that all engines built after December 31, 2009 must reduce the level of emissions exhausted by the engine to the following levels.

Nitrous Oxides (NOx) – 0.2 g/bhp-hr

Particulate Matter (PM)- .01 g/bhp-hr

To meet EPA guidelines, diesel engines installed in Tiffin Motorhomes PowerGlide chassis for domicile in Canada and the USA use an after treatment system (ATS) with a diesel particulate filter (DPF)to reduce particulate matter, and selective catalytic reduction (SCR) technology to reduce NOx downstream of the engine.

Notice

Using non-specification fluids can result in serious damage to the ATS. It is extremely important that the following guidelines be met for vehicles with EPA10 thru EPA2017 compliant engines, or damage may occur to the ATS, and the warranty may be compromised. • Use "ultra-low sulfur diesel (ULSD)" with 15 ppm sulfur content or less.

• Do not use fuel blended with used engine lube oil or kerosene.

• Engine lube oil must have a sulfated ash level less than 1.0 wt %, currently referred to as CJ-4 oil.

• Use only API certified diesel exhaust fluid (DEF) in the DEF tank.

The ATS is comprised of a diesel oxidation catalyst (DOC), and a diesel particulate filter (DPF). The DPF traps soot particles, and exhaust heat converts the soot to ash in the DPF in a process called regeneration (re-gen). The harder an engine works, the better it disposes of soot. When the engine is running under load and re-gen occurs without input, it is called passive re-gen. If the engine isn’t running hot enough, the electronic controls may initiate an active re-gen, whereby extra fuel is injected into the exhaust stream before the DPF, to superheat the soot trapped in the filter and burn it to ash. Both types of re-gen occur without driver input.

Operating at reduced engine load will allow soot to accumulate in the DPF. When this occurs, the DPF lamp

illuminates, indicating that a re-gen must be performed, and the driver must bring the vehicle up to highway speed to increase the load. Driving at highway speeds for 20 minutes should allow for a re-gen to take place, and turn off the DPF lamp. After the exhaust stream passes through the DPF, it flows through a second canister housing which is the SCR device. A controlled quantity of diesel exhaust fluid (DEF) is injected into the exhaust stream where heat converts it to ammonia (NH3) gas. This mixture flows through the SCR device where the ammonia gas reacts with the NOx in the exhaust to produce harmless nitrogen (N2) and water vapor (H2O), which then exits out of the tailpipe.

illuminates, indicating that a re-gen must be performed, and the driver must bring the vehicle up to highway speed to increase the load. Driving at highway speeds for 20 minutes should allow for a re-gen to take place, and turn off the DPF lamp. After the exhaust stream passes through the DPF, it flows through a second canister housing which is the SCR device. A controlled quantity of diesel exhaust fluid (DEF) is injected into the exhaust stream where heat converts it to ammonia (NH3) gas. This mixture flows through the SCR device where the ammonia gas reacts with the NOx in the exhaust to produce harmless nitrogen (N2) and water vapor (H2O), which then exits out of the tailpipe.

ATS Warning Lamps

Warning lamps in the driver’s message center alert you of situations with the after-treatment system.

• An illuminated DPF lamp indicates a re-gen is needed.  Driving at highway speeds for 20 minutes should correct this condition.

Driving at highway speeds for 20 minutes should correct this condition.

o A blinking DPF lamp indicates the need for a re-gen is more urgent. Again, driving the vehicle at highway speeds for 20 minutes should correct this condition.

o A blinking DPF lamp along with a check engine light indicates that the engine is unable to effectively regenerate, and you should immediately seek service at the nearest Cummins Authorized Dealer.

• An illuminated High Exhaust Temperature (HEST) lamp alerts the operator of elevated exhaust temperatures while the engine is performing an active re-gen.  Do not operate, or park the vehicle near flammable objects while the HEST lamp is illuminated.

Do not operate, or park the vehicle near flammable objects while the HEST lamp is illuminated.

• An illuminated DEF warning lamp indicates that the DEF tank should be refilled at the next opportunity.  This light will illuminate when the tank level is at approximately 10%. o A blinking DEF warning lamp indicates the tank level has dropped to approximately 5%.

This light will illuminate when the tank level is at approximately 10%. o A blinking DEF warning lamp indicates the tank level has dropped to approximately 5%.

o A blinking DEF lamp along with the check engine lamp indicates the tank level has dropped to approximately 2.5%. A 25% reduction in engine torque will be applied with this condition.

o When the tank is empty the Stop Engine Light will be illuminated and the vehicle speed will be limited to 5 MPH. Filling the tank with new DEF will remedy this condition.

DPF Maintenance

Eventually ash will accumulate in the DPF and the filter will require servicing. DPF servicing must be performed by an authorized technician, following the engine manufacturer’s instructions. DPF cleaning will be required at approximately 200,000 miles of service. A record must be maintained for warranty purposes, which includes:

• Date of cleaning or replacement

• Vehicle mileage

• Particulate filter part number and serial number

Aftertreatment Operation

Diesel Particulate Filter

Soot is composed of the partially burned particles of fuel that occur during normal engine operation (black smoke).

Ash is composed of the partially burned particles of engine oil that occur during normal engine operation.

Over time, both soot and ash accumulate in the DPF and must be removed. Soot is removed by a process called regeneration. Ash is removed by removing the DPF and cleaning it at specified intervals.

A vehicle with an ATS has up to four additional indicator lamps on the dashboard. These additional lamps, along with the check engine lamp, alert the operator of the status of the ATS.

Ultra low sulfur diesel fuel is required for an engine equipped with a DPF. If ultra low sulfur diesel is not used, the engine might not meet emissions regulations, and the DPF or DOC can be damaged.

To maximize the maintenance intervals of the DPF, Cummins Inc. recommends the use of a lubricating engine oil meeting Cummins Engineering Standard 20081. The use of oil meeting CES 20081 also requires the use of ultra low sulfur diesel fuel to maintain the specified oil drain interval without risk of engine damage.

Regeneration

Regeneration is the process of converting the soot collected in the DPF into ash.

Under some operating conditions, such as low speed, low load, or stop and go duty cycles, the engine may not have enough opportunity to regenerate the DPF during normal vehicle operation. When this occurs, the engine will illuminate the DPF lamp to inform the vehicle operator that assistance is required, typically in the form of operating the vehicle at highway speeds for approximately 20 minutes.

Heat is required for the regeneration process to occur. Regeneration can be classified into two different types: passive regeneration and active regeneration.

Passive Regeneration

Passive regeneration occurs when the exhaust temperatures are naturally high enough to oxidize the soot collected in the DPF faster than the soot is collected.

Passive regeneration typically occurs when the vehicle is driven at normal highway speeds and/or under heavy loads.

Active Regeneration

Active regeneration occurs when the exhaust temperatures are not naturally high enough to oxidize the soot in the DPF faster than it’s collected.

Active regeneration requires assistance from the engine in to increase the exhaust temperature. This is typically accomplished by the engine injecting a small amount of diesel fuel into the exhaust stream, which is then oxidized by the DOC, and creates the heat needed to regenerate the DPF. Active regeneration will occur more frequently in vehicles operated at low speed, low load, or stop and go duty cycles.

Active regeneration only occurs if the engine ECM has detected that the DPF restriction has reached a specified limit, and may only occur if the vehicle is moving above a preset speed threshold. The engine ECM will activate and de-activate active regeneration as needed.

Active regeneration is largely transparent to the vehicle operator, the vehicle operator may notice an increase in turbocharger noise during an active regeneration event, and may notice that the high exhaust temperature lamp is illuminated, if the vehicle is so equipped.

During active regeneration, the exhaust temperature can be hotter than when the engine is operating at full load. The exhaust temperature during a normal active regeneration event could reach 1100°F, and possibly 1500°F under certain conditions.

Warning Active regeneration can occur any time the vehicle is moving, and the exhaust temperature can remain hot after the vehicle has stopped moving. The exhaust temperature could reach 1500°F, which is hot enough to ignite or melt common materials, or to burn people. If the HEST lamp is illuminated do not operate or park the vehicle with the exhaust near people, or flammable materials.

Aftertreatment Warm-up

The ATS warm up function is used to help prevent the buildup of water condensation in the ATS during extended idle operation.

After approximately four hours of engine idle operation, the engine speed will increase to around 1100 RPM, and remain at this speed for 10 minutes. During this time the ATS is warmed up enough to evaporate any water that has condensed in the system.

The ATS warn-up function can be stopped by depressing the throttle, clutch, or brake pedal. If the engine continues to idle, the ATS warm-up function will try to raise the idle speed until the ATS temperatures are suitable.

Engine Indicator Lamps

General Information

The following engine indicator lamps cover only the lamps controlled by the engine ECM.

Wait to Start Lamp

The WAIT TO START lamp illuminates when the intake air heater needs to warm the intake air prior to starting the engine. The WAIT TO START lamp on time will vary depending on the ambient air temperature.

The WAIT TO START lamp is amber and looks similar to this:

Check Engine Lamp

The CHECK ENGINE lamp illuminates when the engine needs to be serviced at the first available opportunity.

The CHECK ENGINE lamp is amber, and looks similar to this:

Another function of the CHECK ENGINE lamp is to flash for 30 seconds at key-on when one of the following occurs. This flashing function is referred to as the MAINTENANCE lamp. The MAINTENANCE lamp could flash for any of the following reasons:

o Maintenance required (if the Maintenance Monitor is enabled).

o Water-in-fuel is detected.

o Coolant level is low.

Stop Engine Lamp

The STOP ENGINE lamp indicates, when illuminated, the need to stop the engine as soon as it can be safely done. The engine must remain shut down until the engine can be repaired.

For engines with the Engine Protection shutdown feature enabled, if the STOP ENGINE lamp begins to flash, the engine will automatically shut down after 30 seconds. The flashing STOP engine lamp alerts the operator to the impending shut down.

The STOP ENGINE lamp is red in color, and looks similar to this:

Malfunction Indicator Lamp (MIL)

The engine in this vehicle is required to conform to EPA Heavy Duty On-Board Diagnostic (OBD) regulations. OBD exist to make sure the engine is operating within the prescribed emissions limits. The OBD system monitors the ATS to detect malfunctions that adversely affect emissions. If a malfunction is detected the malfunction indicator lamp (MIL) will illuminate, and a diagnostic fault code will be logged in the engine control module.

The MIL lamp is amber, and looks similar to this:

Diesel Particulate Filter (DPF) Lamp

The DPF lamp indicates, when illuminated or flashing, that the DPF needs to be regenerated.

The DPF lamp is amber, and looks similar to this:

An illuminated DPF lamp indicates that the DPF needs to be regenerated at the next possible opportunity. This can be accomplished by:

1. Changing to a more challenging duty cycle, such as highway driving, for at least 20 minutes.

2. Have a Cummins authorized repair location perform a stationary regeneration.

NOTE: Stationary regeneration is considered a normal maintenance practice and is not covered by Cummins Inc. warranty.

A flashing DPF lamp indicates that the DPF needs to be regenerated at the next possible opportunity. Engine power may be reduced automatically.

When the DPF lamp is flashing, the operator should:

1. Change to a more challenging duty cycle, such as highway driving, for at least 20 minutes.

2. Have a Cummins authorized repair location perform a stationary regeneration.

A flashing DPF lamp combined with an illuminated CHECK ENGINE lamp indicates that the DPF needs be regenerated immediately. Engine power will be reduced automatically. When these lamps are illuminated together you should immediately seek service from a Cummins authorized repair location.

NOTE: If the engine is unable to complete a DPF regeneration cycle, the STOP ENGINE lamp will illuminate and the vehicle will have to be towed to a Cummins authorized repair location.

High Exhaust Temperature (HEST) Lamp

The HEST lamp is amber, and looks similar to this:

The HEST lamp indicates, when illuminated, that exhaust temperatures are high due to regeneration of the DPF. The lamp could illuminate during normal engine operation or during stationary regeneration.

NOTE: The OEM determines whether or not the HEST lamp is installed on the vehicle. The OEM also specifies the temperatures, vehicle speeds, and other conditions at which the lamp illuminates. Refer to the OEM service manual for additional information regarding this lamp.

When this lamp is illuminated, make sure the exhaust pipe outlet is not directed at any surface or material that will melt, burn, or explode.

o Keep the exhaust outlet away from people, and anything that can burn, melt, or explode.

o Nothing within 0.6 m [2ft] of the exhaust outlet

o Nothing that can burn, melt, or explode within 1.5 m [5ft] (such as gasoline, wood, paper, plastics, fabric, compressed gas containers, or hydraulic lines).

o In an emergency, turn off the engine to stop the flow of exhaust.

NOTE: The HEST lamp does not signify the need for any kind of vehicle or engine service; it merely alerts the vehicle operator to high exhaust temperatures, it will be common for the HEST lamp to illuminate on and off during normal vehicle operation as the engine completes regeneration.

Diesel Exhaust Fluid (DEF) Lamp

The DEF lamp is amber, and looks similar to this:

The DEF lamp indicates, when illuminated or flashing, that the diesel exhaust fluid level is low.

An illuminated DEF lamp indicates that the DEF level has fallen below the initial warning level. This can be corrected by filling the DEF tank with diesel exhaust fluid.

NOTE: It is recommended that the DEF tank be filled completely full of diesel exhaust fluid in order to correct any fault conditions.

A flashing DEF lamp indicates that the DEF level has fallen below the critical warning level. This can be corrected by filling the diesel exhaust fluid tank with diesel exhaust fluid.

NOTE: It is recommended that the DEF tank be filled completely full of diesel exhaust fluid in order to correct any fault conditions.

A flashing DEF lamp combined with an illuminated WARNING or CHECK ENGINE lamp indicates that the DEF level has fallen below the initial derate level. The engine power will be limited automatically. This can be corrected by filling the DEF tank with diesel exhaust fluid.

NOTE: It is recommended that the diesel exhaust fluid tank be filled completely full of diesel exhaust fluid in order to correct any fault conditions.

If the engine has been shut down, idled for 1 hour, or if fuel has been added after the DEF tank has been emptied, the STOP ENGINE lamp will also illuminated along with the flashing DEF lamp and illuminated CHECK ENGINE lamp. The engine vehicle speed will also be limited to 5 mph.

NOTE: In order to remove the 5 mph speed limit, the diesel exhaust fluid tank must be filled to at least 10 percent volume of the tank.

NOTE: It is recommended that the DEF tank be filled completely full of diesel exhaust fluid in order to correct any fault conditions.

Engine Starting

Warning: Do not use starting fluids with this engine. This engine is equipped with an intake air heater. Use of starting fluids could cause an explosion, fire, personal injury, severe damage to the engine, and property damage.

NOTE: For cold-weather starting, see “Cold-Weather Operation” in Section 1 of the Cummins Engine Owner’s Manual.

NOTE: Cummins electronic engines are run on a dynamometer before being shipped from the factory. They do not require a break-in period.

IMPORTANT: Special break-in oils are not recommended for new or rebuilt Cummins engines.

NOTICE If a vehicle does not start on the first attempt, make sure that the engine has completely stopped rotating before reapplying the starter switch. Failure to do so can cause the pinion to release and re-engage, which could cause ring gear and starter pinion damage.

IMPORTANT: Ring gear and starter pinion damage caused by improper starting procedures is not warrantable.

NOTICE Do not crank the engine for more than 30 seconds at a time. Wait two minutes after each try to allow the starter to cool. Failure to do so could cause starter damage.

NOTICE If the engine is equipped with a turbocharger, protect the turbocharger during start-up by not opening the throttle or accelerating the engine above 1000 rpm until normal engine idle oil pressure registers on the gauge.

Starting

Set the parking brake.

1. Place the transmission in neutral.

2. Turn the key to the ON position.

3. Wait a minimum of 10 seconds. If the “Wait-to-Start” lamp is still illuminated after 10 seconds, continue to wait until the lamp is no longer illuminated. The wait to start lamp may stay illuminated for up to 30 seconds depending on ambient temperature.

4. Start the engine.

5. NOTE: See the Cummins Operation and Maintenance Manual for detailed information on starting procedures.

Cold-Weather Starting

Turn the ignition switch to the on position. If the Wait-To-Start lamp is  illuminated, wait until it goes out before trying to start the engine. The Wait-To-Start lamp will stay on for up to 30 seconds. The length of time it remains illuminated depends on the ambient temperature. Once the Wait-To-Start lamp goes off, turn the key to the start position. If the engine doesn’t start after 30 seconds of cranking, turn the key to the off position and wait two minutes; then repeat the starting procedure. Once the engine is started, let it run at idle for 3 to 5 minutes before driving. If normal engine oil pressure doesn’t show on the gauge within 15 seconds of starting, shut the engine off and contact you nearest Cummins authorized repair location for assistance.

illuminated, wait until it goes out before trying to start the engine. The Wait-To-Start lamp will stay on for up to 30 seconds. The length of time it remains illuminated depends on the ambient temperature. Once the Wait-To-Start lamp goes off, turn the key to the start position. If the engine doesn’t start after 30 seconds of cranking, turn the key to the off position and wait two minutes; then repeat the starting procedure. Once the engine is started, let it run at idle for 3 to 5 minutes before driving. If normal engine oil pressure doesn’t show on the gauge within 15 seconds of starting, shut the engine off and contact you nearest Cummins authorized repair location for assistance.

If the unit is equipped with a block heater, start the block heater 2 to 4 hours before travel.

Engine Braking

Important: The engine brake is a vehicle slowing device, not a vehicle stopping device. It is not a substitute for the vehicle service brakes. Use of the engine brake for vehicle downhill control, and slowing down on level terrain will help the service brakes to remain cool and ready for an emergency.

Warning: Do not use the engine brake on wet, icy, or snow-covered roads. Using the engine brake could result in loss of vehicle control, possibly causing personal injury, death, or property damage.

Engine brakes are devices that use the energy of engine compression to provide vehicle retardation. Engine brakes provide maximum retardation while the engine is at rated speed. Therefore, the engine works in conjunction with the transmission to automatically select the best gear for maximum braking efficiency.

The Allison transmission provides for optimum retarding downshift operation. When the engine brake is turned ON, your foot is removed from the throttle pedal, and the service brake is depressed, the transmission will immediately pre-select a lower gear. The transmission then starts to down-shift through gears to reach the pre-selected gear. When the engine brake is active, down-shifting occurs at higher speeds than when it is not active. This allows the engine brake to provide the maximum retarding power.

The engine brake switch in your coach has three positions; off (center position) low, and high. In the low position the engine uses only three cylinders to provide braking effort. In the high position the engine uses all six cylinders to provide braking effort.

The engine brake is activated when the following conditions are satisfied:

1. The engine brake switch is in the low or high position

2. The accelerator pedal is released

3. The service brake is depressed

Cruise Control

Warning: Do not use the cruise control system when driving conditions do not permit maintaining a constant speed, such as in heavy traffic or on roads that are winding, icy, snow covered, slippery, or roads with a loose driving surface. Failure to follow this precaution could cause a collision or loss of vehicle control, possibly resulting in personal injury, death, or property damage.

NOTICE

Cruise control allows you to automatically control the speed of the vehicle above 32 MPH (50 km/h).

Do not shift to Neutral (N) when using cruise control. This will cause the engine to over-speed, which can damage the engine.

Cruise On/Off

Press the cruise control ON/OFF switch to activate the cruise control or to turn it off.

Cruise Set

Press the cruise control SET switch to set the desired cruising speed.

Cruise Resume

Press the cruise control RESUME switch to resume cruise control activation.

Disengage Cruise

Disengage the cruise control by depressing the service brake, or by switching the cruise on/off switch to the off position.

Engine Shutdown

1. With the vehicle stopped, place the transmission in the Neutral (N) position, and set the parking brake using the parking brake control knob.

2. It is important to idle an engine for 3 to 5 minutes before shutting it down. This allows the lubricating oil and the water to carry heat away from the combustion chambers, bearings, shafts, etc. This is especially important with turbo-charged engines.

3. Do not idle the engine for long periods.

4. If the engine is not being used, shut it down by turning the ignition key to the OFF position.

5. Allow a minimum of 3 minutes after the engine is turned off before switching off the chassis battery disconnect.

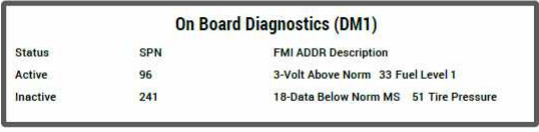

Diagnostic Fault Codes

The engine control (ECM) monitors the engine sensors and parameters while the engine is in operation. The ECM can detect certain conditions that are outside of the normal operating parameters. The ECM will log diagnostic fault information, and illuminate the check engine light, stop engine light, or the malfunction indicator light to inform the operator of a problem. It will also log diagnostic fault information in the form of numeric codes to assist a technician in troubleshooting the concern.

Diagnostic fault codes fall into two categories; active faults, and historic faults. Active faults indicate the condition causing the fault is still present. Historic faults indicate the condition causing the fault is no longer present, but remain in the ECM memory to assist the technician when diagnosing the concern.

Active fault codes can be retrieved by the operator using the dash instrumentation. This can be helpful in determining if the condition is serious, and needs immediate attention, or if it is safe to continue operating the engine until it is convenient for the operator to have the service work performed.

Retrieve active fault codes using the following steps:

Refer to page 33 in the Instruments & controls section of this manual, follow the illustration on page 27 and navigate to the OBD section and retrieve the information listed below.

The desired screen will look like this:

Two pieces of information will be displayed

a. SPN followed by a 3 or 4 digit number

b. FMI followed by a 1 or 2 digit number

Provide these two pieces of information to a Tiffin phone tech, or the nearest Cummins authorized repair location for guidance on how you should proceed.

Towing

The Allegro Phaeton is capable of towing typical motor vehicles or trailers up to 10,000 lbs. The motor home is equipped with a 10,000-pound towing hitch, and associated wiring connector. The total weight of the motor home and any vehicle towed must not exceed the Gross Combined Weight Rating (GCWR). When the motor home is weighed, remember to account for passengers and their locations in the motor home. Any vehicles or trailers to be towed by the motor home should have adequate active braking.